The summarize of plastic floor

1. Names

Several common expressions of plastic floor:

1) PVC: poly vinyl chloride

2) LVT: luxury vinyl tile

3) LVP: luxury vinyl plank

4) Vinyl floor

5) Vinyl plank

6) WPC: wood plastic composite

7) SPC: stone plastic composite, Occident countries call this kind of floor RVP(rigid vinyl plank).

2. Classification

At present, PVC sheet flooring comes in two main types. The first type features a consistent pattern material from the bottom to the surface. In case of any surface damage such as burning or scratching, it can be easily restored through polishing with a grinding machine and applying wax. The second type consists of a pure PVC transparent layer on top, with the bottom layer comprising a composite of a printing layer and foam layer. Clearly, the first type offers more advantages in terms of durability and maintenance.

In terms of format, PVC sheet flooring can be categorized as coiled or in sheet form. Additionally, LVT and WPC fall under the semi-rigid sheet plastic floor category, while SPC (RVP) represents the hard sheet floor type. Moreover, PVC flooring can be further classified into ordinary (Dry Back), lock (click), and non-glue (Loose lay) based on the assembly methods.

The versatility and diverse options within the PVC sheet flooring industry provide a range of solutions for different applications. Whether it is the ease of maintenance, durability, or specific assembly requirements, there are various options available to cater to different needs. As technology continues to advance, the innovation and development of PVC sheet flooring are likely to deliver even more options and possibilities in the future.

3. Composition

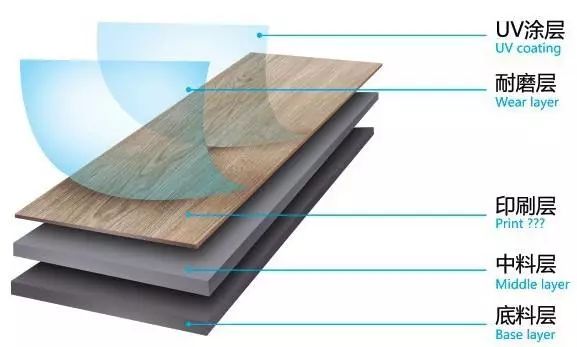

Plastic floor is made of backing layer, core layer, glass fiber, decorative paper and wear layer from the bottom to the surface in turn.

4. Key product index

• Stability: The shrinkage and expansion of the product: 80℃, 6 hours. 0.25%, 0.15%

• Heating buckling: 80℃ 6 hours EN<2mm; 1.2mm (dry back); 1.0mm(click);0.5mm (loose lay)

• Pulling force of lock: Normal atmosphere temperature (23℃): 5.0mm>13-15kgs/5cm, 4.2mm>12kgs/5cm; Short edge use V-shaped lock: 4.2mm>15-18kgs/5cm.

• Peeling strength: The adhesion strength of the color film and the middle material. • Brightness:10+/-2.

5. PVC plastic floor formula

PVC resin, Calcium carbonate, Stabilizer, ACR Processing Aid, Lubricant, CPE, Carbon black.